Top Packaging Trends to Watch Out for in 2024

Posted on 2023-03-20

Tags: #PackagingTrends #PackagingInnovation #SmartPackaging #InternetOfPackaging #IoP #EcoFriendlyPackaging #EnvironmentalSustainability #CircularEconomy #DigitalPrinting #PackagingAutomation #ActivePackaging #CustomerExperience #BrandImage #SustainableMaterials #ReducingPlasticWaste #GreenPractices #DigitalPrintingAdvantages #EfficientPackaging #ProductQuality #ReduceWaste #PackagingFlexibility #CustomizationInPackaging #FunctionalPackaging #EnhancedCustomerExperience #FoodPackaging #ReducingEnvironmentalImpact #InnovativePackagingDesigns

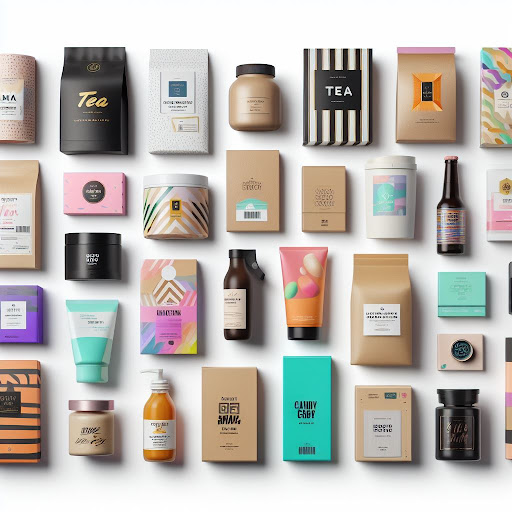

Packaging is not just a way to wrap and ship products. It is also a way to talk to your customers, show off your brand, and care for the planet. The packaging industry is always changing and coming up with new ideas that match what customers, producers, and the environment want. In this blog post, we will look at some of the top packaging trends that will make a big difference in 2024 and beyond.

.jpg)

Smart Packaging

One of the coolest trends in the packaging industry is making packaging smarter and more connected. This is called smart packaging or internet of packaging (IoP), and it means adding digital features to packaging that make it more useful, convenient, and valuable. For example, smart packaging can let customers scan a code or a tag on a package and get more information, such as what’s inside, when it expires, how to use it, what other people think, how to give feedback, how to join a loyalty program, and more. Smart packaging can also let producers track and check their products throughout the supply chain, and see how they are doing in terms of temperature, humidity, freshness, etc. Smart packaging can help brands create more personal and fun experiences for their customers, as well as improve their work and green practices.

.jpg)

Eco-Friendly Packaging

Another big trend in the packaging industry is making packaging more eco-friendly and less harmful to the environment. Plastic is the most common packaging material since the early 20th century, but it also causes a lot of environmental problems because it lasts for a long time and does not break down easily. According to a report by the World Economic Forum, there will be more plastic than fish in the oceans by 2050. To solve this problem, many packaging companies are making and using eco-friendly packaging materials that are made from natural sources, such as paper, cardboard, wood, bamboo, corn starch, mushroom, seaweed, etc. These materials can break down into harmless substances within a few months or years, depending on the conditions. Eco-friendly packaging can help reduce waste and greenhouse gas emissions, as well as support circular economy principles.

.jpg)

Digital Printing

Digital printing is another trend that is changing the packaging industry. Digital printing means printing directly from a digital file onto a surface, such as paper, plastic, metal, glass, etc. Digital printing has many benefits over traditional printing methods, such as offset lithography or flexography. For example, digital printing allows for faster delivery times, lower costs, higher quality, more flexibility, and customization. Digital printing can let producers make small batches or individual packages with different designs, colors, texts, images, etc. This can help brands reach different markets, make seasonal or limited-edition packages, or personalize packages for specific customers. Digital printing can also encourage innovation and creativity in package design by allowing for more complex and detailed graphics.

.jpg)

Packaging Automation

Packaging automation is another trend that is making the packaging industry more efficient and productive. Packaging automation means using machines and software to do various tasks in packaging production and distribution, such as filling, sealing, labeling, palletizing, etc. Packaging automation can help save labor costs, human errors, material waste, and energy use, as well as increase speed, accuracy, consistency, and safety. Packaging automation can also make packaging operations more flexible and adaptable by allowing for easy changes in package size, shape, or format. Packaging automation can help packaging companies meet the growing demand for high-quality, diverse, and customized packages.